We've experience nothing but grief with this 6-port engine; nothing seems to fit right.

When we tried to mount the exhaust manifold, we found that the Racing Beat manifold doesn't quite fit on the the engine like the stock thermal reactor/afterburner would. At first, we didn't think this was such a bad thing, but then we noticed that it wasn't covering all the exhaust ports. There are two smaller ones that are connected to the main ports, but exit the irons a little bit below the main port. We think they were used to actuate the secondaries on the intake, but we're not certain. In any event, they're no longer needed so we needed to find a way to plug them

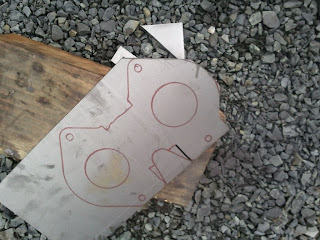

Our idea was to get a piece of metal and make a plate that can be mounted over the studs first, blocking off the extra exhaust ports but leaving the main ports open, then mount the exhaust manifold over that. Seems simple enough, right?

The main problem is that not any metal will do. The exhaust gas of a rotary engine is in the neighborhood of 1,700 degrees F; plenty hot enough to burn through most metals given enough time and high RPMs. The stock exhaust system was specifically designed to deal with the extreme temps: made of iron and weighing as much as a diesel tractor. We decided on a piece of cast gray iron, which melts at about 2,200 degrees F.

Turns out metal dimensions are a little like wood dimensions (a 2x4 is not 2" by 4", but more like 2 3/4" by 3 1/2"), only in reverse. We ordered a 1/4" think plate and it turned out to be closer to 1/2". That led to a slight problem with the length of the studs, but we figured out that we could remove them from the block and revers them, giving us extra threaded length where we needed it.

Van set to work on "machining" the plate down to the size and dimensions needed to fit on the studs, and to cover the extra exhaust ports yet leave the mains open. I say "machining" because he managed to do it all with an angle grinder, a drill, and a hammer - pretty impressive. It can best be described as...homely. But it works! Well, so far it works; we haven't started the car yet...

Van was successful in removing the JB weld from the power brake port on the manifold and after chasing the threads out and installing a fitting, we're ready to install. We getting closer...

No comments:

Post a Comment