Racing Seat and

Harness Installation In 90 (or so) Easy Steps -by resident seat and harness expert, Van

I will explain in an easy to follow, step-by-step manner how

you too can install a racing seat and six point racing harness. Please allow 3

months for completion.

Warning!!

Installing a racing seat

requires the use of dangerous power tools in conjunction with alcohol

consumption. Always use appropriate eye

and hearing protection (unless you can’t remember where your goggles are, or

you can see them, but they are clear on the other side of the garage and going

and getting them is really a hassle), and always use good judgment (for

instance, always decide against building a race car).

1) Spend

months agonizing over which seat to buy.

Keep in mind the following criteria:

a. Drivers

come in all shapes and sizes & they all need to fit in the seat,

b. The

seat needs to meet LeMons rules,

c.

You want to be able to install a slider so that

the seat is adjustable,

d. You

will need to be able to install a seat back brace.

Things to worry about later:

e. The

seat needs to fit in the car,

f.

Rule changes may make your purchase obsolete.

When deciding which seat to buy, price is

going to be an issue. It’s tempting to

go the less expensive route, but remember, this thing is going to protect your

life in the event of an accident. On the

other hand, money you save on a seat purchase can be used to buy beer.

2) Wait

practically forever for the seat to arrive.

3) Open

the big box that the seat has been shipped in.

Bask in its shiny glory. Enjoy

how wonderful the seat looks now because once the installation begins, the

polished aluminum glow will fade and you will learn to hate the filthy thing

with all your heart.

4) Go

to the hardware store and purchase all the fasteners you will need (nuts,

bolts, washers, fender washers, lock washers, locking nuts, & jam nuts).

5) Test

fit the seat in the race car. Take

special note that the door won’t close because the seat is too wide. Also note

that it seems to sit pretty high in the car.

Probably too high for the driver’s helmeted heads to be within the roll

cage.

6) Remove

seat from car.

7) Cut

section out of transmission tunnel and cut rear factory seat mounting bracket out

of driver’s floor.

8) Carefully

measure opening in transmission tunnel and fabricate cardboard template to

cover hole.

9) Duplicate

cardboard template by painstakingly cutting & trimming a piece of aluminum.

10) Using

a heavy brass hammer and block off wood, pound aluminum into approximate shape

to fill hole.

11) Fasten

new transmission tunnel into place using rivets, nuts, bolts, and RTV.

12) Drink

a beer and tell yourself that it’s actually a good thing that your handiwork

looks like crap.

13) Carefully

study instructions that came with seat slider assembly. Marvel at how money and trees have been saved

by printing the installation instructions on a 3 inch by 4 inch piece of paper

that contains absolutely no useful information (in four languages!).

14) Spend

a couple of hours installing seat sliders to bottom of seat via trial and

error.

15) Install

seat mounts to bottom of sliders.

16) Put

seat in car and decide, “Well, that’s never going to work!”

17) Remove

seat from car.

18) Trim

seat mounts to fit better.

19) Put

seat in car.

20) Remove

seat from car and trim more.

21) Repeat

steps 19 & 20 until seat fits (about 200 times).

22) Put

seat back in car and screw around trying to get the thing to line up.

23) Decide

that the fasteners you bought don’t include everything you needed to finish

this today and 5 hours of this bullshit is enough for one day.

24) Drink

a beer.

25) Stop

at hardware store to buy more fasteners.

26) Put

seat in car and mark holes for drilling through floor boards.

27) Remove

seat from car and drill holes in floor boards.

28) Put

seat in car and find that the holes don’t line up. Scratch head and wonder how the hell that

could have happened.

29) Mark

additional spots for drilling, remove seat from car, open a beer.

30) Put

seat in car and bolt in. Discover that

the slider allows for almost an entire inch of forward and backward movement!!

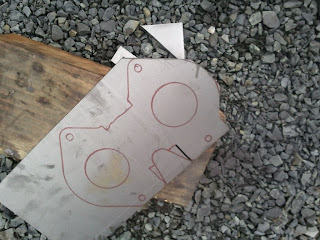

Seat

test fitment

31) Take

car to roll cage builders.

32) Figure

out team name.

33) Design

team T-shirts.

34) Wonder

if you are ever going to see the car again.

35) Drink

beer.

36) Today’s

the day! Pick up the car from the roll cage builders.

37) Find

out that the seat fit is even tighter than you thought. Race seat will need to “toe out” at the front

in order for driver to clear roll cage.

Cage builder has done you a huge favor though and welded bolts into the

factory seat brace so that you don’t need to go through the floor (thanks

Doug!)

38) Take

car home and test fit seat. Discover

that new holes will need to be drilled in the floor pan.

39) Drill

holes and wonder at which point the bottom of the car goes from being “a piece

of steel with holes drilled in it” to “a big hole with some steel still in the

way”.

40) Mount

seat in car.

41) Have

tallest driver get in car and discover that the top of his helmet might be too

high.

42) Email

LeMons technical guru for roll cage clearance clarification.

43) Drink

beer.

44) Check

email and find out that seat will definitely need to be lowered.

45) Remove

seat from car.

46) Remove

Slider from seat (that thing was a POS any.

Glad to see it go.).

47) Attach

seat mounts directly to seat and put back in car. Discover that with the seat sliders gone, you

are going to need to drill holes in the seat itself to mount the front of the

thing.

48) Remove

seat from car and carefully measure locations for new holes.

49) Drill

new holes and tell yourself that without side windows, a few holes in the

bottom of the car will be handy for allowing rain to drain out.

50) Mount

seat in car.

Making the seat fit with the roll cage

installed

51) Rear

mounts are too high, remove seat from car.

52) Take

a drink of beer.

53) Try

to get some warmth and feeling into your fingers and wonder where you put your

gloves.

54) Trim

mounts and put seat in car.

55) Repeat

steps 51 through 54 until seat fits.

Frozen steel and aluminum will suck the heat right out of your hands.

56) Have

tallest driver get in seat with helmet on and find that clearance is more than

adequate.

57) Success!!

Enjoy a beer!!

58) Find

out from further reading of the rules that the seat is now too LOW because

shoulder harnesses are coming through the seatback at a down angle.

59) Give

thanks that you still have one seat mount that has not felt the spinning,

grinding edge of a cutting disk yet.

60) Drill

more holes, cut more aluminum, and finally wrestle the seat into a position

that works inside the car.

Installing seat back brace

61) Discover

that rather than 8 months until the next LeMons race, you actually have 4

months.

62) Order

racing harness (thankfully you actually researched this before hand and have a

pretty good idea of what you need.

63) Receive

racing harness and mounting hardware (ordered separately).

64) Remove

seat.

65) Follow

instructions explicitly for mounting of anti-submarine belts. Hey, that was easy!

66) Mount

seat.

67) Agonize

over locations for lap belts.

68) Screw

that, install the shoulder belts. Another

success.

69) Decide

on lap belt location and remove seat.

70) Drill

your holes.

71) Attach

one lap belt. So far, so good.

72) Mount

other lap belt…. WTF? This one is

different from the other 5?! Looks like

mounting the final belt will have to wait.

Oddball lap belt connector.

73) Drink

a beer.

74) Luckily,

CR is there and works with guys that fabricate stuff from steel all day long. Even more luckily, CR brought over a couple

of growlers of micro-brew.

75) Attach

lap top belt with zip ties and try harness.

76) Drink

some micro-brew. That’s the stuff!

77) Anti-submarine

belts don’t reach and mounts will need to be moved forward.

78) Remove

seat and relocate anti-submarine mounts.

Anti-submarine belt installation, take

2. Actually took 3 tries as the 3” inch

harness clips needed to be replaced with 2” harness clips. How many holes can you count?

79) Drink

some micro-brew.

80) Install

seat and check anti-submarine belt length.

That’s close.

81) Send

CR a drawing of what you need fabricated.

82) Get

bracket from CR. Thanks CR!!

83) Install

new bracket. Works perfect!

84) Install

se… WTF? New bracket is interfering with

the right rear seat mount.

85) Remove

seat and trim seat mount.

86) Test

fit seat.

87) Repeat

85 & 86 until seat fits.

88) Install

seat for the last time (Ha!). Job

complete!!

89) Find

the gloves that you were missing in step 53.

Success!

Bask in the glory. Sure, the seat

no longer has that “brand new” look that it had when you bought because you

drilled a bunch of holes in it, and you don’t have any use at all for that

fancy Italian slider, and the aluminum mounting brackets have been cut more

times than -----------------, but the job is done. And done well! Well enough, anyway.

That’s

the abridged version. In actuality, the

seat was removed and installed in the car absolutely no less than 100 times.