Finally!

After two solid days of thrashing on the primary transmission, we finally got it together. It's not assembled exactly per the service manual, but the manuals are so poorly written that it's impossible to follow them exactly. There are a few parts left over but that's normal, right?

Our initial plan was to finish up the assembly of the gear section, then look into whether we were going to have to re-clock the shift rods or not. The latter is the most delicate part of this whole deal; if we screw them up, we could be out of a primary transmission for the next race which was just two weeks away.

Getting the gear section together turned out to be the easy part, as we predicted. Re-clocking the shift rods turned out to be pretty easy too, as they matched the originals perfectly and worked with the 2nd gen shifter linkage. The problem turned out to be with final assembly of the transmission case. Every time we tightened down the housing bolts and the front cover, we could not get the input shaft to turn, even in neutral. It also would not shift into most gears without twisting the input shaft back and forth.

We proceeded to spend the rest of the weekend assembling and disassembling the damn thing probably a dozen times to varying degrees, trying to figure out what was causing the binding. We went through a tube and a half of sealant because every time we thought we had it sorted out, we re-applied the stuff only to have to tear it down again. What a waste...

We found that the thing that was really causing the problem was tightening down the front cover. We ended up isolating the cause down to too much axial load on the input shaft bearing. In layman's terms, the front cover was pushing in on the bearing, loading it up and causing too much friction.

We ended up having to remove a retaining ring and pressing the bearing further onto the input shaft. We put the cover back on and the binding was gone. The only problem is, now we can't put the retaining ring back on!

So the question is, have we built a transmission that's sure to fail, or have we custome-built one of the most reliable, race-ready transmissions money can('t) buy?

We'll find out next weekend...

Tuesday, July 10, 2012

Part 24

Labels:

lemon,

LeMons,

Mazda,

rotary,

RX7,

speedchimp,

transmission,

wankel

Part 23

Frankenstein-ing a New Transmission

As none of us really have a ton of experience rebuilding transmissions, we tapped the expertise of our buddy Darren. He's a mechanic for Honda with at least a decade of transmission rebuilds under his belt. Darren went through all of our parts and gave a yea or nay as to their re-usability. Turns out most of the synchros in the 2nd gen gearbox we had are toast. That's no big deal as we didn't intend to use them anyway. Some of the parts in our original gearbox should not have been re-used, but I used them anyway; it's just too damned expensive to buy new parts for a 30+ year old transmission. Besides, it's our spare.

Van and Darren spent quite a bit of time working on assembling the Miata gearbox while Carl and I worked on other stuff. There was a lot of cursing, a lot of "how's THAT supposed to work?", and a lot of "screw this, I quit". The final nail in the coffin for the day was the fact that we had either misplaced or thrown away a big locking nut that was needed for reassembly. On to the beer drinking...

The following weekend, with missing parts ordered and received (where would we be without the internet and UPS?), we reconvened to (hopefully) finish up this reassembly. Too bad the part that we'd received was not the correct part. So we had to wait for a few more weeks to get the right part...

As none of us really have a ton of experience rebuilding transmissions, we tapped the expertise of our buddy Darren. He's a mechanic for Honda with at least a decade of transmission rebuilds under his belt. Darren went through all of our parts and gave a yea or nay as to their re-usability. Turns out most of the synchros in the 2nd gen gearbox we had are toast. That's no big deal as we didn't intend to use them anyway. Some of the parts in our original gearbox should not have been re-used, but I used them anyway; it's just too damned expensive to buy new parts for a 30+ year old transmission. Besides, it's our spare.

Van and Darren spent quite a bit of time working on assembling the Miata gearbox while Carl and I worked on other stuff. There was a lot of cursing, a lot of "how's THAT supposed to work?", and a lot of "screw this, I quit". The final nail in the coffin for the day was the fact that we had either misplaced or thrown away a big locking nut that was needed for reassembly. On to the beer drinking...

The following weekend, with missing parts ordered and received (where would we be without the internet and UPS?), we reconvened to (hopefully) finish up this reassembly. Too bad the part that we'd received was not the correct part. So we had to wait for a few more weeks to get the right part...

Labels:

LeMons,

Mazda,

rotary,

RX7,

speedchimp,

transmission,

wankel

Part 22

Transmission Woes

A busted transmission cut our first race short, taking us out just about an hour after the green flag on Sunday. This was something that obviously had to be addressed/repaired before the next race.

In the forums, when we described our race weekend and what had happened, someone suggested that we could improve the gearbox by getting ahold of a later-model Miata gearbox and modifying it to fit our RX-7 drive train. The Miata gearbox is stronger and has a better set of ratios than our stock box, so it sounded like a good idea. All we had to do was:

- Find a Miata transmisson

- Disassemble it and replace any worn parts

- Disassemble a 2nd gen transmission (which we already had as a spare)

- Send both input shafts out to have the Miata shaft machined down to the correct length

- Reassemble the Miata gearbox

- Re-clock the shift rods to work with the 2nd gen shift linkage

- Bolt on the 2nd gen bell housing and tail shaft housing

We also needed to figure out what went wrong with the original transmission because we wanted to fix it so we could keep it as a spare. Disassembly was fairly easy, even though the factory service manual is a POS. But one thing became clear pretty quickly: getting the thing back together was going to be much more difficult than getting it apart.

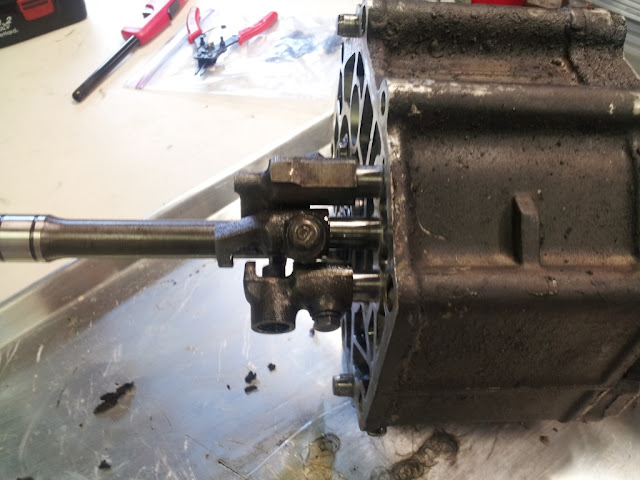

Here's the actual "gearbox", with the bell housing and tail shaft housing removed.

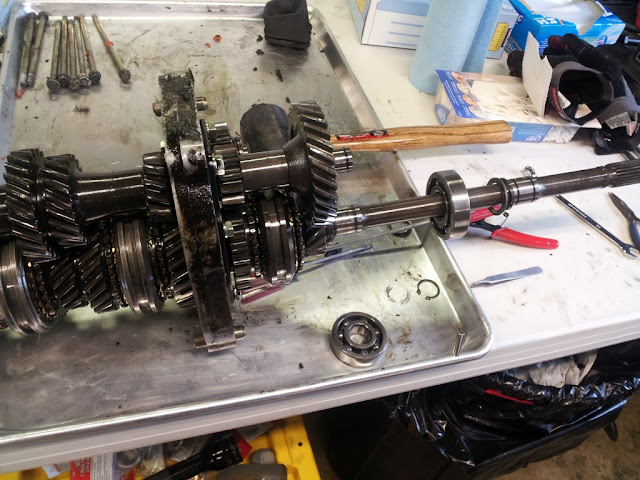

These are the shift rods. Each rod controls two gears.

This is a view of the same end, but looking into the box.

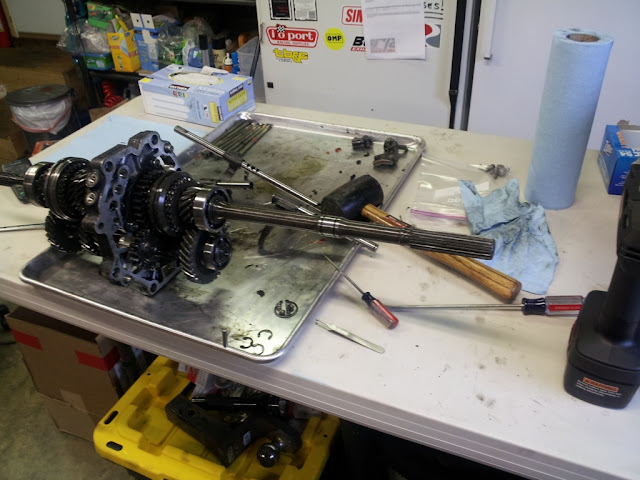

This pic shows the gear and synchro sets (most of them, anyway). On the left are the shift rods and forks.

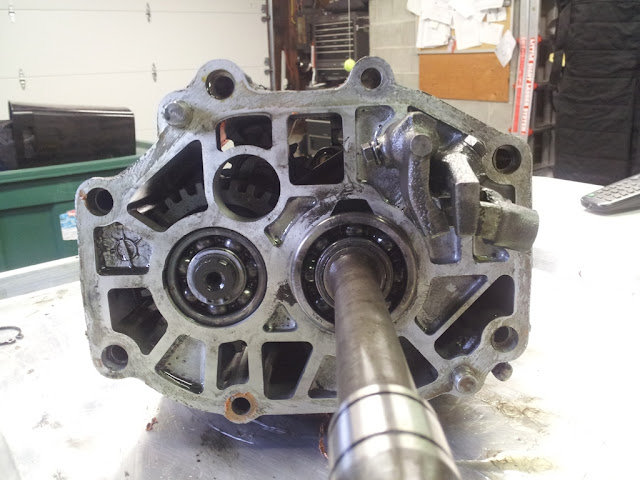

Gearbox with the housing removed.

A lot of these pics I took just so I'd know what it looked like before I tore it apart.

With everything torn down...

An important thing about rebuilding a transmission is the installation of the bearings. You don't want to pound on them too much or in the wrong way or you'll damage them. After that, it's just a matter of putting everything on the main shaft, input shaft, and lay shaft in the right order and in the right orientation. If you can turn the input shaft and the output shaft turns in each gear, that's a pretty good sign. All told, it probably took me 5-6 hours to rebuild my first transmission.

I'd like to say "and that's all there is to it", but that's not exactly the case. I had just finished rebuilding the engine and I wanted to get it into the car and get it running. You can't really install the engine by itself due to the way the engine and transmission are mounted in the car. I ended up installing this transmission (our backup box) temporarily so we could run the engine. For some reason, even though it was working perfectly before, it now would not shift into 3rd or 4th gears. It was stuck pretty good.

So out it came...again. I'm getting pretty good at dropping the transmission out the bottom of the car...

I knew the general area the problem would be found in; it's the same shift rod for both gears so it had to be something with the rod, the detents (ball bearings that keep the shift rods in place when a gear is selected), or the synchros. Carl was over that day and helping me out, so it was a lot easier getting it apart then doing it all yourself.

We took the covers off and, of course, the problem disappeared. I inspected the shift rod, the fork, the synchro; all looked good and were now working properly. We removed the shift switches (used for emissions signaling, reverse lights, etc.) and I noticed that one had a thick aluminum washer/spacer and the other one didn't. The washer definitely made a big difference on how far the switch housing protruded into the case, and the clearance between the shift fork and the switch. I inspected the switch housing and found some wear marks; looks like a root cause to me...

We reassembled the transmission and everything seems fine; that could have ended a lot worse.

One transmission down, one to go...

Labels:

lemon,

LeMons,

Mazda,

racing,

rotary,

RX7,

speedchimp,

transmisson

Spring/Summer Update

I know it's been radio silence since the last race in March. We actually needed a little time to decompress and to review the pluses and minuses that were realized at Sears Point. We've been busy, and I've neglected keep the blog up to date. The next few posts will be a summary of what we've been up to...

Subscribe to:

Comments (Atom)