Finally!

After two solid days of thrashing on the primary transmission, we finally got it together. It's not assembled exactly per the service manual, but the manuals are so poorly written that it's impossible to follow them exactly. There are a few parts left over but that's normal, right?

Our initial plan was to finish up the assembly of the gear section, then look into whether we were going to have to re-clock the shift rods or not. The latter is the most delicate part of this whole deal; if we screw them up, we could be out of a primary transmission for the next race which was just two weeks away.

Getting the gear section together turned out to be the easy part, as we predicted. Re-clocking the shift rods turned out to be pretty easy too, as they matched the originals perfectly and worked with the 2nd gen shifter linkage. The problem turned out to be with final assembly of the transmission case. Every time we tightened down the housing bolts and the front cover, we could not get the input shaft to turn, even in neutral. It also would not shift into most gears without twisting the input shaft back and forth.

We proceeded to spend the rest of the weekend assembling and disassembling the damn thing probably a dozen times to varying degrees, trying to figure out what was causing the binding. We went through a tube and a half of sealant because every time we thought we had it sorted out, we re-applied the stuff only to have to tear it down again. What a waste...

We found that the thing that was really causing the problem was tightening down the front cover. We ended up isolating the cause down to too much axial load on the input shaft bearing. In layman's terms, the front cover was pushing in on the bearing, loading it up and causing too much friction.

We ended up having to remove a retaining ring and pressing the bearing further onto the input shaft. We put the cover back on and the binding was gone. The only problem is, now we can't put the retaining ring back on!

So the question is, have we built a transmission that's sure to fail, or have we custome-built one of the most reliable, race-ready transmissions money can('t) buy?

We'll find out next weekend...

SpeedChimp Racing

News and pics of our racing exploits

Tuesday, July 10, 2012

Part 24

Labels:

lemon,

LeMons,

Mazda,

rotary,

RX7,

speedchimp,

transmission,

wankel

Part 23

Frankenstein-ing a New Transmission

As none of us really have a ton of experience rebuilding transmissions, we tapped the expertise of our buddy Darren. He's a mechanic for Honda with at least a decade of transmission rebuilds under his belt. Darren went through all of our parts and gave a yea or nay as to their re-usability. Turns out most of the synchros in the 2nd gen gearbox we had are toast. That's no big deal as we didn't intend to use them anyway. Some of the parts in our original gearbox should not have been re-used, but I used them anyway; it's just too damned expensive to buy new parts for a 30+ year old transmission. Besides, it's our spare.

Van and Darren spent quite a bit of time working on assembling the Miata gearbox while Carl and I worked on other stuff. There was a lot of cursing, a lot of "how's THAT supposed to work?", and a lot of "screw this, I quit". The final nail in the coffin for the day was the fact that we had either misplaced or thrown away a big locking nut that was needed for reassembly. On to the beer drinking...

The following weekend, with missing parts ordered and received (where would we be without the internet and UPS?), we reconvened to (hopefully) finish up this reassembly. Too bad the part that we'd received was not the correct part. So we had to wait for a few more weeks to get the right part...

As none of us really have a ton of experience rebuilding transmissions, we tapped the expertise of our buddy Darren. He's a mechanic for Honda with at least a decade of transmission rebuilds under his belt. Darren went through all of our parts and gave a yea or nay as to their re-usability. Turns out most of the synchros in the 2nd gen gearbox we had are toast. That's no big deal as we didn't intend to use them anyway. Some of the parts in our original gearbox should not have been re-used, but I used them anyway; it's just too damned expensive to buy new parts for a 30+ year old transmission. Besides, it's our spare.

Van and Darren spent quite a bit of time working on assembling the Miata gearbox while Carl and I worked on other stuff. There was a lot of cursing, a lot of "how's THAT supposed to work?", and a lot of "screw this, I quit". The final nail in the coffin for the day was the fact that we had either misplaced or thrown away a big locking nut that was needed for reassembly. On to the beer drinking...

The following weekend, with missing parts ordered and received (where would we be without the internet and UPS?), we reconvened to (hopefully) finish up this reassembly. Too bad the part that we'd received was not the correct part. So we had to wait for a few more weeks to get the right part...

Labels:

LeMons,

Mazda,

rotary,

RX7,

speedchimp,

transmission,

wankel

Part 22

Transmission Woes

A busted transmission cut our first race short, taking us out just about an hour after the green flag on Sunday. This was something that obviously had to be addressed/repaired before the next race.

In the forums, when we described our race weekend and what had happened, someone suggested that we could improve the gearbox by getting ahold of a later-model Miata gearbox and modifying it to fit our RX-7 drive train. The Miata gearbox is stronger and has a better set of ratios than our stock box, so it sounded like a good idea. All we had to do was:

- Find a Miata transmisson

- Disassemble it and replace any worn parts

- Disassemble a 2nd gen transmission (which we already had as a spare)

- Send both input shafts out to have the Miata shaft machined down to the correct length

- Reassemble the Miata gearbox

- Re-clock the shift rods to work with the 2nd gen shift linkage

- Bolt on the 2nd gen bell housing and tail shaft housing

We also needed to figure out what went wrong with the original transmission because we wanted to fix it so we could keep it as a spare. Disassembly was fairly easy, even though the factory service manual is a POS. But one thing became clear pretty quickly: getting the thing back together was going to be much more difficult than getting it apart.

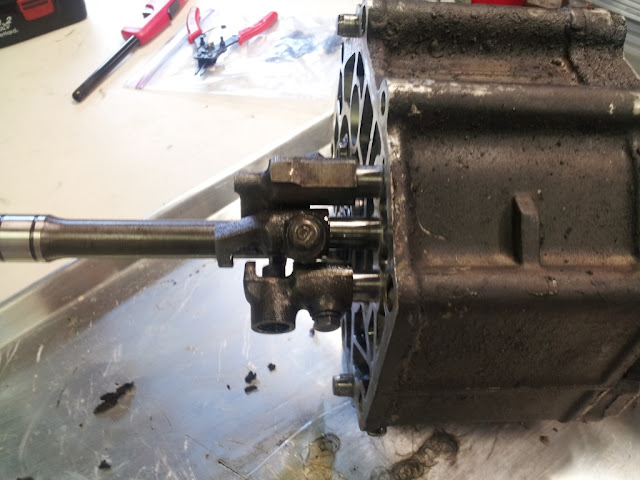

Here's the actual "gearbox", with the bell housing and tail shaft housing removed.

These are the shift rods. Each rod controls two gears.

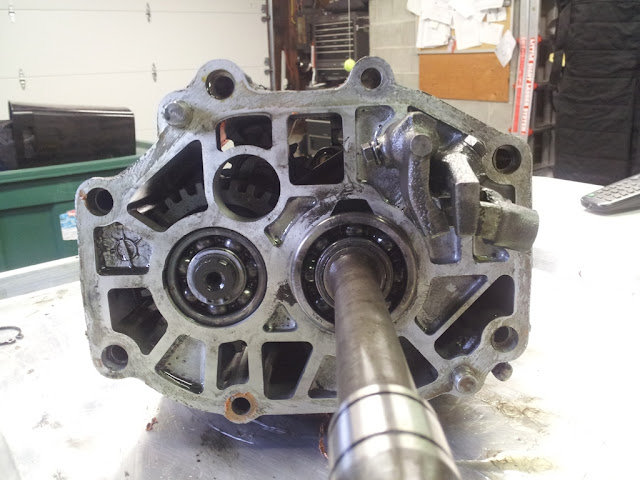

This is a view of the same end, but looking into the box.

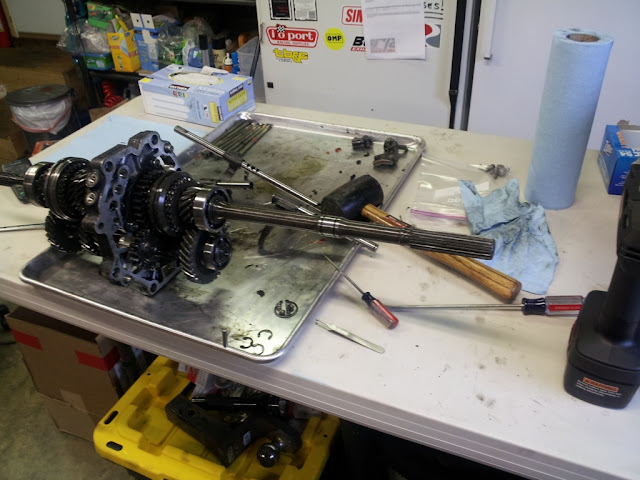

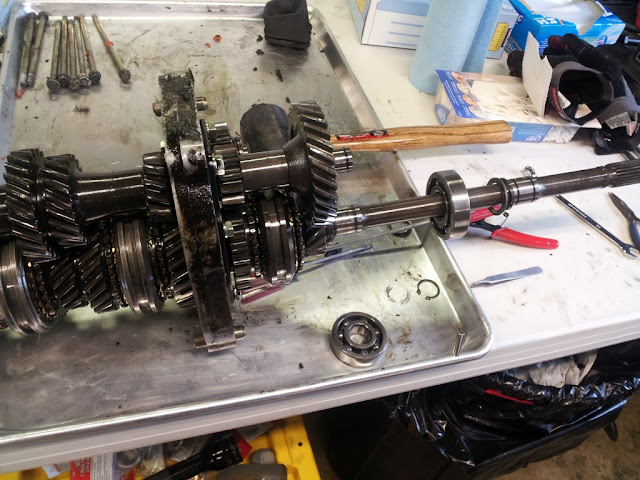

This pic shows the gear and synchro sets (most of them, anyway). On the left are the shift rods and forks.

Gearbox with the housing removed.

A lot of these pics I took just so I'd know what it looked like before I tore it apart.

With everything torn down...

An important thing about rebuilding a transmission is the installation of the bearings. You don't want to pound on them too much or in the wrong way or you'll damage them. After that, it's just a matter of putting everything on the main shaft, input shaft, and lay shaft in the right order and in the right orientation. If you can turn the input shaft and the output shaft turns in each gear, that's a pretty good sign. All told, it probably took me 5-6 hours to rebuild my first transmission.

I'd like to say "and that's all there is to it", but that's not exactly the case. I had just finished rebuilding the engine and I wanted to get it into the car and get it running. You can't really install the engine by itself due to the way the engine and transmission are mounted in the car. I ended up installing this transmission (our backup box) temporarily so we could run the engine. For some reason, even though it was working perfectly before, it now would not shift into 3rd or 4th gears. It was stuck pretty good.

So out it came...again. I'm getting pretty good at dropping the transmission out the bottom of the car...

I knew the general area the problem would be found in; it's the same shift rod for both gears so it had to be something with the rod, the detents (ball bearings that keep the shift rods in place when a gear is selected), or the synchros. Carl was over that day and helping me out, so it was a lot easier getting it apart then doing it all yourself.

We took the covers off and, of course, the problem disappeared. I inspected the shift rod, the fork, the synchro; all looked good and were now working properly. We removed the shift switches (used for emissions signaling, reverse lights, etc.) and I noticed that one had a thick aluminum washer/spacer and the other one didn't. The washer definitely made a big difference on how far the switch housing protruded into the case, and the clearance between the shift fork and the switch. I inspected the switch housing and found some wear marks; looks like a root cause to me...

We reassembled the transmission and everything seems fine; that could have ended a lot worse.

One transmission down, one to go...

Labels:

lemon,

LeMons,

Mazda,

racing,

rotary,

RX7,

speedchimp,

transmisson

Spring/Summer Update

I know it's been radio silence since the last race in March. We actually needed a little time to decompress and to review the pluses and minuses that were realized at Sears Point. We've been busy, and I've neglected keep the blog up to date. The next few posts will be a summary of what we've been up to...

Wednesday, April 25, 2012

Part 21

Sears Pointless 2012 was a weekend of firsts. It was our first race, and our first DNF (did not finish). We learned a lot of lessons and while we may not be perfect for Pacific Northworst in July, we should be at least 100% better...

Wednesday

We were scheduled to get on the road about 5pm, mainly because Carl had to work that day. He ended up getting off quite a bit earlier, so we were able to get going around 2:30. That was nice because no one wanted to get into Eugene at midnight, but it was also a curse because there are about a half dozen items that were forgotten due to all the rushing around to leave early. Good job, Carl...

After plowing through nearly white-out conditions in the Willamette Valley, we reached the RV park around 10pm. Not too bad, and even better that I could enjoy a cold beverage...

Thursday

We did the bulk of the driving on Thursday, from Eugene to Sears Point (510 miles). Driving through Fairfield and Vallejo sucked because it was rush hour and the other drivers did not give an ounce of shit that we were driving an RV and a pickup towing a 30' car trailer...

We arrived at the track just about at dusk, found we couldn't really get unloaded until the next morning, so we parked the vehicles in the lot up the hill from the paddock and enjoyed some good steaks and cocktails.

Friday

Friday was a busy day. We got the trailer unloaded and the car set up because we were going to participate in the test & tune session that day (we'd had zero opportunity to test the car before). We couldn't find our brake fluid (turns out we didn't bring it), and we had a few items we needed to finish up on the car.

Test & tune turned out to be a bust as the car was not running well at all. The car ran one lap under it's own power, then the push truck had to bring us in (which smashed the hell out of Van's baby, the rear wing he'd put so much effort into). So much for the "DO NOT PUSH" sticker on the back of the car...

We battled fuel issues for several hours before we finally got it fixed (clogged fuel line, just before the filter). Too bad there are no pics of me buried under the back of the car, I was filthy after that...

In fact, we went through tech and Bullshit inspections with a car that wouldn't run for longer than 12 seconds at high RPMs...

After we finished inspections and got the car running, we were able to relax a little and kind of soak in the experience. Friday night isn't too much of a party, but there were lots of cars to see and other teams to chat up. We received quite a few compliments on how "clean" and "pretty" our car looked.

Saturday

The weather had been great so far, but that was all about to change. A wet weather system had moved in overnight and it was due to stick around all weekend. Boy, did it rain. I mean real rain; not the drizzle we get in Seattle. It rained pretty solid all day Saturday and into Sunday morning.

After the driver's meeting (for which we were so properly attired), the race got started about 9:30am.

Our pit stops were miserably slow and completely uncoordinated, which contributed to less than desirable ratio of time on the track to time in the pits. Definitely some room for improvement. We also experienced some radio issue, which we need to work out before the next race...

SpeedChimp Racing Black Flag Club inducted it's two charter members at Sears Point, with two black flags on Saturday (you get 5 before they shut you down for the weekend). Melissa got one for spinning out in the 9a chicane (turns out that more throttle is NOT what's needed when the rear end breaks loose)...

Her penalty was a stern talking-to by the judges with advice to slow down.

Van was also black-flagged for a spin at 3a (I believe) during his second stint (sorry, no pics). Van's penalty was that he had to get out of the car, even though he'd only been on-track for about 15 minutes. They made us switch drivers (which we were NOT ready for...) and go back through the penalty box to prove it.

We finished the day in 128th place of 170 cars. Not too bad for our first race.

After the Saturday session ended at 6pm, we got in some quick dinner then came back down to the paddock to service the car (check brakes, change the oil, clean the windows, etc.). After that, we were free to mingle. Saturday night is the big party night at a LeMons race. Teams are showing off their cars, spying on the competition, and of course the cocktails flow endlessly.

Sunday

The rain abated early Sunday, and over the morning the track started to dry out. The Sunday session started at 10am with Van taking the first stint, and the car was getting quicker and quicker. This was due mainly to the track drying out, but also to Van getting more familiar with the car.

We'd planned to up the stint length to 90 minutes, which is just about how far we think the car can go on one tank of fuel. Van was about an hour and 10 minutes into his stint and we were up to 123rd place with a team fast lap of 2:30.44 on the 101st lap

Then tragedy struck...

Over the crackle of the radio we hear the bad news.

"The car is broken, I'm coming in. The transmission's stuck in 3rd gear."

Our hearts sank. Was this something we could fix? We have a spare transmission...

When the car made it back to our pit stall, we set to work on it. I drove up to the trailer and grabbed the spare transmission. We pulled the broken gear box out of the car and started changing over all the external parts to the spare, then we noticed the first issue: the shifter won't fit into the turret correctly. The locating pin is on the opposite side...

To make a long and painful story short, instead of trying to install the shifter backwards to see if it would at least work, we proceeded to disassemble two transmissions in an attempt to make one that would fit in the car. In the end, all we did was waste time and effort, and it ended up putting us out of the race; we just ran out of time to get the car back on track.

So we packed it up and rolled out early. The silver lining (if you can call it that) is that we were able to reach Redding a little earlier than expected (10pm or so). And a good thing too, because we needed a drink to drown our sorrows...

Monday

We completed the trip home on Monday (600 miles), and were glad to be done with driving.

Summary

We learned a LOT in this race. Everyone did a fantastic job in their first ever wheel-to-wheel racing experience. We've already come a long way in the 4 weeks since the race, identifying areas for improvement, and we're really looking forward to the race in Shelton, July 21st and 22nd. But there's a lot to do between now and then...

You can see all the pics here.

Wednesday

We were scheduled to get on the road about 5pm, mainly because Carl had to work that day. He ended up getting off quite a bit earlier, so we were able to get going around 2:30. That was nice because no one wanted to get into Eugene at midnight, but it was also a curse because there are about a half dozen items that were forgotten due to all the rushing around to leave early. Good job, Carl...

After plowing through nearly white-out conditions in the Willamette Valley, we reached the RV park around 10pm. Not too bad, and even better that I could enjoy a cold beverage...

Thursday

We did the bulk of the driving on Thursday, from Eugene to Sears Point (510 miles). Driving through Fairfield and Vallejo sucked because it was rush hour and the other drivers did not give an ounce of shit that we were driving an RV and a pickup towing a 30' car trailer...

We arrived at the track just about at dusk, found we couldn't really get unloaded until the next morning, so we parked the vehicles in the lot up the hill from the paddock and enjoyed some good steaks and cocktails.

Friday

Friday was a busy day. We got the trailer unloaded and the car set up because we were going to participate in the test & tune session that day (we'd had zero opportunity to test the car before). We couldn't find our brake fluid (turns out we didn't bring it), and we had a few items we needed to finish up on the car.

Test & tune turned out to be a bust as the car was not running well at all. The car ran one lap under it's own power, then the push truck had to bring us in (which smashed the hell out of Van's baby, the rear wing he'd put so much effort into). So much for the "DO NOT PUSH" sticker on the back of the car...

We battled fuel issues for several hours before we finally got it fixed (clogged fuel line, just before the filter). Too bad there are no pics of me buried under the back of the car, I was filthy after that...

In fact, we went through tech and Bullshit inspections with a car that wouldn't run for longer than 12 seconds at high RPMs...

Saturday

The weather had been great so far, but that was all about to change. A wet weather system had moved in overnight and it was due to stick around all weekend. Boy, did it rain. I mean real rain; not the drizzle we get in Seattle. It rained pretty solid all day Saturday and into Sunday morning.

After the driver's meeting (for which we were so properly attired), the race got started about 9:30am.

The Team

(Left to right: Carl, Van, Roger, Melissa, Mike)

We decided to do short, 30-minute stints so that we'd all get a chance to get some track time in case the car broke down early. We actually finished the entire day on Saturday, with everyone getting to drive at least two stints. And we proved that our car will not be suffering from any maladies related to water...Our pit stops were miserably slow and completely uncoordinated, which contributed to less than desirable ratio of time on the track to time in the pits. Definitely some room for improvement. We also experienced some radio issue, which we need to work out before the next race...

SpeedChimp Racing Black Flag Club inducted it's two charter members at Sears Point, with two black flags on Saturday (you get 5 before they shut you down for the weekend). Melissa got one for spinning out in the 9a chicane (turns out that more throttle is NOT what's needed when the rear end breaks loose)...

Her penalty was a stern talking-to by the judges with advice to slow down.

Van was also black-flagged for a spin at 3a (I believe) during his second stint (sorry, no pics). Van's penalty was that he had to get out of the car, even though he'd only been on-track for about 15 minutes. They made us switch drivers (which we were NOT ready for...) and go back through the penalty box to prove it.

We finished the day in 128th place of 170 cars. Not too bad for our first race.

After the Saturday session ended at 6pm, we got in some quick dinner then came back down to the paddock to service the car (check brakes, change the oil, clean the windows, etc.). After that, we were free to mingle. Saturday night is the big party night at a LeMons race. Teams are showing off their cars, spying on the competition, and of course the cocktails flow endlessly.

Sunday

The rain abated early Sunday, and over the morning the track started to dry out. The Sunday session started at 10am with Van taking the first stint, and the car was getting quicker and quicker. This was due mainly to the track drying out, but also to Van getting more familiar with the car.

We'd planned to up the stint length to 90 minutes, which is just about how far we think the car can go on one tank of fuel. Van was about an hour and 10 minutes into his stint and we were up to 123rd place with a team fast lap of 2:30.44 on the 101st lap

Then tragedy struck...

Over the crackle of the radio we hear the bad news.

"The car is broken, I'm coming in. The transmission's stuck in 3rd gear."

Our hearts sank. Was this something we could fix? We have a spare transmission...

When the car made it back to our pit stall, we set to work on it. I drove up to the trailer and grabbed the spare transmission. We pulled the broken gear box out of the car and started changing over all the external parts to the spare, then we noticed the first issue: the shifter won't fit into the turret correctly. The locating pin is on the opposite side...

To make a long and painful story short, instead of trying to install the shifter backwards to see if it would at least work, we proceeded to disassemble two transmissions in an attempt to make one that would fit in the car. In the end, all we did was waste time and effort, and it ended up putting us out of the race; we just ran out of time to get the car back on track.

So we packed it up and rolled out early. The silver lining (if you can call it that) is that we were able to reach Redding a little earlier than expected (10pm or so). And a good thing too, because we needed a drink to drown our sorrows...

Monday

We completed the trip home on Monday (600 miles), and were glad to be done with driving.

Summary

We learned a LOT in this race. Everyone did a fantastic job in their first ever wheel-to-wheel racing experience. We've already come a long way in the 4 weeks since the race, identifying areas for improvement, and we're really looking forward to the race in Shelton, July 21st and 22nd. But there's a lot to do between now and then...

You can see all the pics here.

Friday, March 16, 2012

Part 20

A Glimpse Inside

the Speedchimp Racing Aerodynamics Laboratory

Part 1 – The Idea

& The Concept

24 Hours or LeMons entries can roughly be lumped into four

types of cars/teams:

Type 1 – Teams that show up with and race a complete pile of

crap that should have been left in the wrecking yard (probably the most

prevalent type of entry).

Type 2 – Teams that show up with a really, really good theme

including costumes and either an over-the-top art car, or a really good parody

of a real race car (a replica of the Oscar Meyer wienermobile or a car with a

20’ blimp attached to the roof).

Type 3 – Teams that show up with a heavily modified

monstrosity of car (a Miata with a working moonshine still or a car powered by

a 90 year old airplane motor).

Type 4 – Teams that show up with a car that is completely

unsuitable for racing (a stretch Limousine for example).

Getting accepted to a race is very dependant on the 24 Hours

of LeMons judges being intrigued by your entry and we

at Speedchimp Racing had a minor problem.

Even though our car really is a 30+ year old piece of crap, it didn’t really look that bad. When we started working on it, we began

finding some serious problems, but many people who saw the car were surprised

that we weren’t going to just fix it up and sell it for a profit. Something else we learned after purchasing

the car is that the LeMons community considers Mazda RX-7s to be a little bit

on the “cheaty” side (An opinion that is completely unfounded in my opinion). For instance, the 1st Generation

RX7 utilizes a live rear axle (which can also be found on pickup trucks, Ford

Mustangs, mini-vans, and other vehicles known for superior handling)

incorporating a Watts Linkage; the cutting edge of 18th century steam

engine technology.

We weren’t a Type 1 team because our car was too nice. We weren’t a Type 3 team because frankly, we

don’t have the tools or skills to make those kinds of modifications. And we weren’t a Type 4 team because regardless

of antiquated mechanical design, the RX-7 is still considered a sports car with

an actual history of winning races.

That left us as a Type 2 team and presented a new

problem. With the exception of Melissa,

none of us are really what you would consider to be “dress up” people. Costumes?

Ugh… That story can be covered in another chapter. I’m going to

concentrate on the transformation of our worn out RX7 into a fast looking race

car.

During the whole creative process for developing our car and

theme, we really wanted to stay away from ideas that had already been to

death. Pretty early on we decided that

we should pretend our car was something that it very obviously was not, but we

didn’t know exactly what. We had some

ideas, but nothing that we were really in love with. Instead of worrying about the theme, we decided

to focus on the huge amount of work the car needed.

Fast forward to the summer of 2011 with my wife and I

cleaning and organizing our garage.

While digging through the junk we had accumulated over the years, I came

across a stack of drawings from the various drafting classes I had taken in

Junior High and High School. Buried in

the stack was a technical drawing I had done of an early ‘80s BMW M1

Procar. “Hmm,” I thought, “That bears a

strong resemblance to our Mazda”. Later

that day I searched the interwebz for pictures of BMW M1s. While actual photographs of a BMW M1 looked a little bit like an RX-7, it was

clear that the A- I had received for my drawing was based more on technique

than actual resemblance to the source material.

Still, we hadn’t come up with anything better in the mean time, so I

decided to run an idea by the team.

Mazda RX-7

The resemblance is uncanny!

The idea:

Decorate the car to look like a BMW M1 Procar with the iconic tri-colored diagonal

stripe. How hard could it be to fabricate some kind of air dam and a rear wing?

Also, our car would be a parody of the M1, so a perfect copy wasn’t really the

point. Instead of calling it a BMW

(Bavern Motor-Werken), our car would be an RBW (Reis Brenner-Wagen or Reis

Brenner-Wankel). We could wear lederhosen, talk with funny accents, and walk

around saying, “I know nuttink”. It would be funny!

The idea was met with some skepticism (“Dude, really? I am

skeptical that you are going to get me to wear lederhosen.”), doubt (“I doubt I

will wear lederhosen.”), and lack of vision (“Lederhosen? I do not see myself

wearing short leather pants”). On the other hand, so far it was pretty much the

only idea, and therefore, the best idea.

There were some pros though; our car was already white, so

painting would be relatively easy. And…

Actually, aside from

looking pretty cool, that was the only pro.

Time passed and the RBW theme gradually settled into

everyone’s minds as the shortest, easiest route to LeMony glory.

There would be five main components to transforming our car

into the mighty RBW7.

1) The

Concept (RBW)

2) The

Wing,

3) The

Air Dam,

4) The

Grill, and,

5) The

Paint.

It would have been nice if these projects were completed in

some sort of orderly manner, but this is Real Life. They weren’t.

There were ups, there were downs, there were unexpected plot twists, and

most of all, there were setbacks.

Rather than try to retell all that occurred in historical

order, it is probably best to address each project on its own…

The Concept (RBW)

The RBW logos were actually the first thing completed

(thanks to Mike). They turned out rather

well we think…

Reis-Brenner Wagen (Rice Burner Wagon)

Part of the LeMons application process requires the team to

explain its theme and why your team should be accepted to race (there are

routinely more applicants than available grid positions and the judges are

looking for “quality” entrants). We fabricated

a story about a fictional German automaker named RBW, threw in some enticing

(and possibly misleading) hints about bribes for the judges and posted a

picture of the wrong car. And we were

accepted!

Part 2 - The Wing

The Wing was the second project to get started (and the last

to be finished). The first concept for

The Wing was nothing more than a piece of plywood bolted to the back of the car

and painted white. Then I thought,

“Hey. I’ve got months to build this

thing so why don’t I make an actual wing-shaped wing?” The Wing Mk I was

fabricated by cutting plastic and layering the pieces into an airfoil shape

with a piece of steel tubing running the span to provide strength. At this point I had a pretty LeMony wing that

would have suited our purposes and I could have easily left well enough alone.

I could have been finished.

I could have begun working on something else. But I didn’t because something happened…

Completely unrelated to work on the car, I was made aware of

a NASA website that allowed for modeling of wings under different

conditions. It was easy enough to plug

in the data for our wing and see how much downforce it would make (hardly any

at all). Playing with the software

showed that adding camber to the wing shape (see pictures) would increase the

efficiency of The Wing and create 30 times as much downforce. With camber, our wing would actually work.

Our wing needed camber!

Wing with no camber in the chord

Wing with camber in the chord

I just didn’t know how to go about making it happen.

I knew that the ABS our wing was built from had a pretty low

melting point, so I thought maybe I could just heat the plastic and bend it to

the shape I wanted. I mentioned to Mike

that I needed some kind of a tube so that I could heat the ABS to the point it

became pliable, then use the tube as a form.

Mike suggested that a cardboard tube used for making concrete forms

might work. After performing a little

research and doing some math, I determined that a 12” diameter tube (available

at Home Depot) would give The Wing 12.5 degrees of camber. Perfect.

Then I tried to form the ABS.

And the ABS did not want to form around the tube. I had made a pretty big error. Between the steel and plastic used to build

it, The Wing weighed about 15 pounds.

The thing simply had too much thermal mass to heat to a point of

pliability without completely melting and blistering the outer layers. Also,

although the cardboard tube was the perfect shape and length, it didn’t really

have much strength, so trying to bend the plastic around it was causing the

tube to deform. This clearly wasn’t working.

I had already managed to deform a corner

of The Wing rendering it useless as a zero camber airfoil. I was back at square one.

The plans for The Wing Mk II had two substantial changes; 1)

rather than layer alternating pieces of 24” and 12” pieces of ABS, the wing

would be built completely from 48” long pieces of ABS, and, 2) The Wing would

be clad in aluminum sheet. This should

be strong enough to prevent The Wing from exploding into a hundred pieces of

shredded plastic should there actually be any aerodynamic forces acting upon

it. There was no way that this plan

could fail.

After working on The Wing the night of February 29th,

I decided that my plan was a failure. I

simply didn’t have the proper equipment to accomplish what I was trying to do

and the results of my efforts were terrible (and likely dangerous). I had already been thinking about The Wing Mk

III as a future project for the car and I really had no choice but to abandon

my efforts with ABS and go straight to a full aluminum design.

The construction of The Wing Mk III began with designing the

ribs and overall size of the airfoil.

The specifics are:

Span: 44”Chord: 9”

Chord Thickness: ≈10% (about an inch thick)

Camber: ≈11%

I cut a prototype rib out of a piece of aluminum and decided it was good. Attempting to exactly duplicate the shape was difficult (it is almost impossible to cut through 4 stacked pieces of 1/8” aluminum sheet with any kind of accuracy). I ended up employing a “Snowflake” manufacturing technique. No two parts were exactly alike.

Attempting to cut all the ribs at one time (unsuccessfully)

While this was going on in my garage, I was also planning the wing uprights. The biggest challenge here was fastening the uprights to the trunk lid. I wanted the uprights to be as far outboard as possible, but the space inside the car to secure the fasteners was limited. The uprights eventually ended up mounted 38” apart. But The Wing had a span of 44”. In a metal working shop, a tool called a “Brake” would be used to make precision bends in the aluminum. The brake we have is nowhere near capable of bending 1/8” aluminum so an alternate method was required. Several methods failed before a solution was discovered. The method that worked went as follows:

1) Place a 12” long

chunk of wooden 4”X6” on the garage floor.

2) Place aluminum upright on wood block.

3) Place second piece of 4”X6” on top of aluminum.

4) Carefully align the desired line of bend with edges of wooden blocks.

4) Carefully align the desired line of bend with edges of wooden blocks.

5) Kneel on top wooden block.

6) Bash aluminum with 15Lb anvil until desired shape is

achieved. This process took hours (instead of the minutes it would have taken with the correct tools) and required some fine tuning (bashing) with a brass mallet, but the desired bends were achieved and the scars were quickly painted over.

Wing Upright in place

Meanwhile, the lack of proper tools was causing the building

of The Wing to take much longer also. I

needed 72 brackets cut from a piece of L shaped aluminum. This would have been easy work with a bandsaw,

but the job was very slow going using only a hacksaw.

Pile of (72) Brackets

Once these were cut, each was matched with a specific location on a rib and marked, and then drilled using the high precision tools available in my garage.

Speedchimp Racing precision drilling station

After the brackets had all been drilled, they were matched

up with each rib and riveted into place.

Rib #5 with custom brackets and completed rib assemblies

The ribs were then JB Welded to a ½” square steel tube. The steel tube would serve two purposes; strengthen The Wing and allow a threaded steel rod to pass through the middle of the wing to tie the two uprights together. An additional aluminum bar was JB Welded into place on the lower side trailing edge of the wing to keep the ribs parallel and to provide an anchor point for the skin of the wing when I began riveting it in place.

Letting the JB Weld cure

After allowing the JB Weld to cure, I began putting the skin into place. I won’t go into the details, but my first attempt at skinning The Wing was a catastrophe. The second attempt at skinning The Wing went much better and was almost completely free of drama or significant problems.

The skin going on The Wing

Skin in place

With the skin in place, the last step of construction was to

build end plates. I originally was going

to build these out of aluminum, but I didn’t like the thickness or strength of

any of the aluminum that I had in the garage.

I decided to use a piece of steel that I had lying around. Designing the end plates consisted of; 1)

tracing the outline of airfoil shape on a piece of graph paper, 2) determining

the imaginary line running through the airfoil that equaled a zero degree angle

of attack, 3) finding the imaginary line that equaled a 13 degree angle of

attack (this was determined to be the angle at which The Wing would generate

the most downforce), and 4) drawing the outline of an endplate that looked

decent. Once the design work was done,

the shapes were cut out of the steel plate and riveted to the ends of the wing.

End plates in place and bare metal coated with primer

Part 3 - The Air Dam

The Air Dam is the bit of fabrication that had me the most

concerned. By its very nature, The Air

Dam was going to be subject to aerodynamic forces and occasionally dragging on

the ground and thus would need to have good inherent strength. Design and fabrication was also going to be

difficult because of the shape of the front of the car. In short, I really was not looking forward to

this part of the build because I had very little confidence that this would

turn out decent at all and I really had no idea how to accomplish what I wanted.

Planning consisted primarily of looking at pictures of BMW M1s and thinking about how to shape and mount the thing. I briefly considered making The Air Dam from aluminum, but decided that ABS would be cheaper in the long run (because I expected to make many mistakes and be forced to start from scratch and ABS costs a lot less). We had been working on the car for months and I finally decided that the plans in my head weren’t going to execute themselves, so I broke out a tape measure and started estimating the amount of material I would need.

During planning, I couldn’t find a piece of ABS big enough

to make the entire thing out of one piece.

A minimum of two were going to be required. The ABS I selected came in

36”X36”X1/8” sheets. I decided to form

one half and see how it went. I drew

some rough lines on the piece of ABS and went after it with a scoring tool and

a heat gun.

36” X 36” X 1/8” Sheet of ABS

I had an idea of how the thing should look and fit together with the car, but I struggled to get a design on paper. I was pretty sure that this was going to be a complete failure…

The first cuts and bends

What happened next was pretty surprising. The pieces were fitting on the car the way I had envisioned. Sure, they weren’t perfect and no one would call the results “pretty”, but it was actually working!

Test fitting the first half of The Air Dam

After getting the first half finished, the next trick was duplicating the effort to make a matching second piece. “Easy”, right? I was afraid of it being “too easy” and making a horrible mistake, so I really took my time to make sure that the cuts were all going in the right place (a mirrored shape of the first piece). It worked pretty well. The next step was to fasten the two pieces together. This was accomplished by sandwiching the plastic between sheets of aluminum then riveting the whole assembly together. The drilling and riveting was actually the most time consuming portion of the entire project. Approximately 80 rivets were used for fastening and strengthening The Air Dam.

When mounted on the car, it actually looked pretty

good. Not completely on center (I made

quite a few eyeball measurements and estimations during fabrication) and it

definitely has a homemade look, but a surprisingly cool result for a project

that I had been dreading and with amazingly few mistakes made and material wasted.

The finished Air Dam in place

Finishing touches included adding threaded rods to the

leading edge of the splitter (for both strength and adjustability) and JB

Welding nuts to the inside of the fenders so that The Air Dam could be removed

without completely disassembling what was to come next…

Part 4 - The Grill

This was another project that I was dreading, primarily

because I only had a very vague idea of how to do it. I already had ABS that I had originally purchased

for the Air Dam but decided not to use because the sheets were only 24” X 12”

and ¼” thick. Due to the size of the

opening in the front of the car, I was going to have to use 3 sheets somehow

fastened together.

Melissa had been eager to help with the car so she was

tasked with fabricating a prototype out of cardboard. She finished the job in record time and it

was perfect. Unfortunately I didn’t take

any pictures of her pattern, but the pictures of The Grill that follow are

exact duplicates of the pattern she created, so obviously, she nailed it.

The first steps went quickly; layout ABS pieces & tape

them together. Tape Melissa’s pattern to

the plastic and trace an outline. Use a

straight edge to clean up lines and ensure that measurements are consistent

between both sides. Use a drill and step

bit to cut radii into corners, use a jigsaw to make straight line cuts.

I knew that heating and bending plastic this thick was going

to be a challenge, so the pieces that needed big adjustments were placed into

the oven to heat soak. Then we used a

heat gun to soften the plastic where the bends needed to be.

While I was cutting the plastic, Carl was cutting and

painting expanded steel mesh that would fasten the three pieces together and

provide the same sort of vents as the real M1.

Next came the actual assembly. Drilling holes and popping rivets.

Assembling the driver’s side and center section (note the notch cut to

clear the tow hook)

The finished Grill

The final part of assembly was figuring out how to mount the

grill to the car. This turned out to be

pretty easy. Fasteners at each end and

three custom fabricated brackets in the middle were enough to robustly install

the thing.

Part 5 - The Paint

As I had mentioned, the original plan was to paint the car in classic BMW M1 Procar (a mid-‘80s BMW M1 specific racing series) colors; tri-color stripes on a white field.

Plan A (it looked so easy!)

Our plan had a lot going for it. With the car already white, the paint job

would be relatively easy and the car was going to be instantly recognizable to

anybody that knew anything about BMW “Works” colors. It was the “recognizable” factor that turned

out to be a problem. By this point in

time we had been doing LeMons research for quite a while and one of the things

that our research turned up was that the paint scheme we planned to do had been

already been done. Not just once, but

quite a few times, including two cars at the same race with this paint scheme. Our stunningly original and clever idea was a

dud. After a lot more surfing the

intertubes and discarding a few other ideas for paint schemes, we decided to go

with classic Marlboro livery which had been used by a couple different BMW M1s. We didn’t want it to actually say “Marlboro”

though (R.J. Reynolds wasn’t actually sponsoring us, why advertise for them?),

so the search was on for a Marlboro parody.

We finally settled on Laramie (an actual cigarette brand that went out

of business in the ‘50s). Laramie is a

brand of cigarettes satirized on The Simpsons.

Sure, the idea wasn’t particularly original (or our own), but we were

beginning to feel a time crunch.

Plan B

Painting was relatively easy. Find a few decent pictures of the real

car. Tape things off and apply paint

with rollers and brushes.The results are stunning and speak for themselves…

Subscribe to:

Comments (Atom)